REMOVING CONCRETION COMPLETE…ALMOST

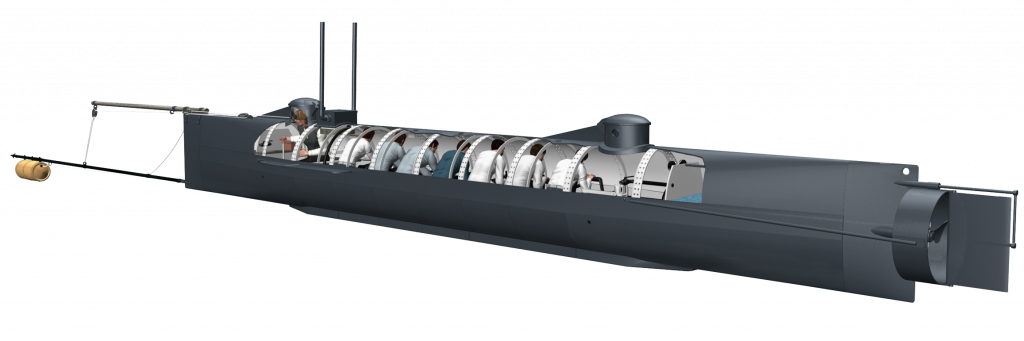

With the interior crew compartment and outside surface cleaned of the layer of concretion, the multi-year concretion removal project is nearly complete. The exceptions are small patches of concretion that remain in the hard-to-reach corner areas in the forward and aft ballast tanks. Though conservators think they will find a solution to reach the forward section, the aft tank is small and the submarine’s operational machinery blocks access to it.

EXHAUSTING WORK

Removing the concretion was physically and mentally exhausting. Conservators stayed curled up in various awkward positions for hours working in the small crew compartment. One mistake, drop of a tool or slip-of-the-hand could cause permanent damage to the fragile artifact.

Removing the concretion was physically and mentally exhausting. Conservators stayed curled up in various awkward positions for hours working in the small crew compartment. One mistake, drop of a tool or slip-of-the-hand could cause permanent damage to the fragile artifact.

Johanna Rivera-Diaz, a Clemson University Conservator spearheading the deconcretion project, said, “Removing the concretion was a slow and challenging task for all of us involved, but the ability to get an up-close look at the true surface of the submarine after all this time has made it entirely worth it.”

Now that the Hunley has been mostly cleaned of this material, the vessel will sit in

a conservation bath for approximately five years to preserve the metal and make her ready for permanent public display.

With the interior crew compartment and outside surface cleaned of the layer of concretion, the multi-year concretion removal project is nearly complete. The exceptions are small patches of concretion that remain in the hard-to-reach corner areas in the forward and aft ballast tanks. Though conservators think they will find a solution to reach the forward section, the aft tank is small and the submarine’s operational machinery blocks access to it. The team is examining different ways to reach these last areas to remove concretion without physically being inside the tanks.

OTHER DISCOVERIES UNCOVERED…

Removing concretion from the inside of the crew compartment produced other interesting finds:

Human Remains

A tooth was found near where it is believed Frank Collins sat in the 3rd crank position. His remains were buried in 2004 alongside his crewmates and others that lost their lives in the testing and development of the Hunley.

Crank Harder!

A complex gear system helped enhance the output of the crew’s hard work when cranking the submarine over four miles to their target. Cranking that far was no doubt exhausting and this innovative design feature helped lighten the load for the eight-man crew.

Unusual Indention

A roughly 3-centimeter circular indention in the cast iron bow was made visible when removing the concretion material. Some initially speculated this could be damage left from small arms fire. This appears unlikely since the divot is located roughly mid-way down the bow, well below the waterline. Archaeologists say it could be a casting flaw caused by an air bubble in the iron when the submarine was being built in 1863.